|

This system automates the task of producing a technically correct print,

making printing faster, easier and safer.

In these prints you could refind all fine

details of the negative as it automatically determine and set the optimal contrast grade and exposure time and this without any preceding test prints or perfect print the „hard way“.

|

|

|

Special features

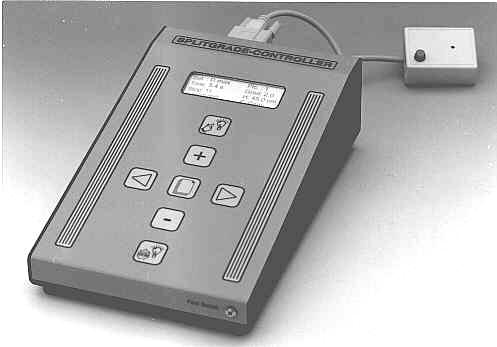

To achieve perfect prints,it is equipped with a control unit, with a microprocessor,

a probe and a filter head with step motor. By passing the probe through the image,

the probe scans the image, looks for the brightest and the darkest part and calculates the best contrast grade and exposure time for this particular negative. The controller then splits the exposure time in two parts, deciding

how long the negative will be printed through the yellow and the succeeding magenta filter.

In this way a technically perfect print is realised where the shadows are 90%

black and the highlights white, with still enough detail to show all information

contained in the negative.In function of: the general density the density differences

the paper type used the film type to print the unit

manages the whole printing process and this without any preceding test prints! Due to the sensitometric knowledge and experience integraded in the program, the only job you have to do is: load the

negative, compose

the print, look for the brightest and the darkest parts in the negative, position the paper in the enlarging easel and print.

It is clear that this system saves on time and paper and contributes to creativity by

letting the machine do the toilsome technical work.

|

|

|

Technical specifications of the control unit

measuring probe: probe for exposure and gradation reading automatic

automatic setting of filter module and operating panel acoustic support by

beeper. diameter of reading point: Ø 3mm

exposure control: built-in exposure timer and light shutter

measuring range:

0.01 - 10Ix (10 stops)

exposure time range: 1 -200 sec.

resolution: 0.1 sec.

time accuracy failure: <0.5%, repeatability < 0.1%<

gradation input:

automatic in 0.1 steps after reading of the contrast

manual input gradation: in 0.1 steps with automatic density control

manual input gradation time: in 0.1 sec. steps with constant gradation

basis of measurements: ca. 90% of maximal paper density

grad tables: factory adjusted for 9 papers (main brands: ILFORD, KODAK, AGFA) and 4 films, actualisation y disk or internet

interfaces:

reading probe, foot switch, RS232

display: illuminated LCD display with 4 lines

voltage: 90 to 250 V, 45 to 65 Hz

dimensions (BxTxH) 160x22260x80mm

weight:

ca. 1 kg without accessories

delivery contains: controller, filter module, probe, footswitch,

electrical appliances

|

|